- Home

- About us

- Products

- Wooden Spoon Making Machine

- Wooden Ice Cream Stick Machine

- Wooden Tongue Depressor Stick Making Machine

- Wooden Coffee Stirring Stick Making Machines

- Wooden BBQ Stick Making Machine

- Wooden Toothpick Making Machine

- WOOD WORKING MACHINE

- Bamboo Toothpick Machine

- Bamboo Chopstick Machine

- Bamboo BBQ Stick Machine

- Bamboo Flooring Machine

- Bamboo Stick Making Machine

- Bamboo Charcoal Making Machine

- Bamboo Powder Making Machine

- Bamboo Toothbrush Machine

- Bamboo Spoon,Fork, Knife Making Machine

- Accessories

- Incense Stick Making Machine

- Plastic Machine

- BAMBOO PRODUCTS

- Other Projects

- Cotton Bud Making Machine

- New Machines

- Faqs

- News

- Certificate

- Contact us

Wooden Fork Teeth Milling Machine (teeth making)

- group name

- wood spoon fork making machine

- Min Order

- 1 set

- brand name

- Besta

- model

- CBJ-1

- Nearest port for product export

- Shanghai, Shenzhen, Ningbo

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C

- Export mode

- Export through agents

- update time

- Tue, 25 Aug 2020 20:25:55 GMT

Paramtents

wooden spoon making machine wooden fork making machine

Packging & Delivery

-

Min Order1 set

Briefing

WOODEN FORK MAKING MACHINE

WOODEN KNIVES MAKINGMACHINE

Detailed

WOODEN SPOON MAKINGMACHINE

WOODEN FORK MAKING MACHINE

WOODEN KNIVES MAKINGMACHINE

WOODEN PLATE MAKING MACHINE

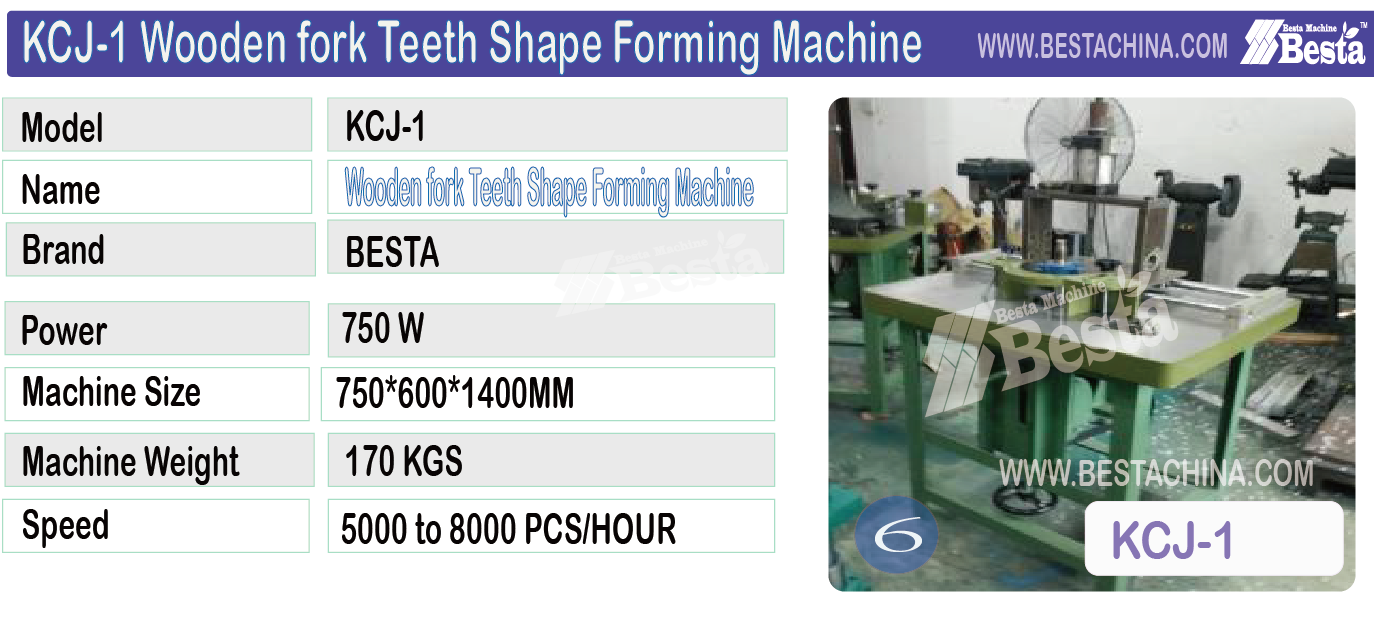

Model: KCJ-1

Name: Wooden Fork Teeth Making Machine

Power: 750W

Machine Size: 750*600*1400MM

Weight: 170 KGS

Manufacturing Speed: 5000 to 8000 PCS/Hour

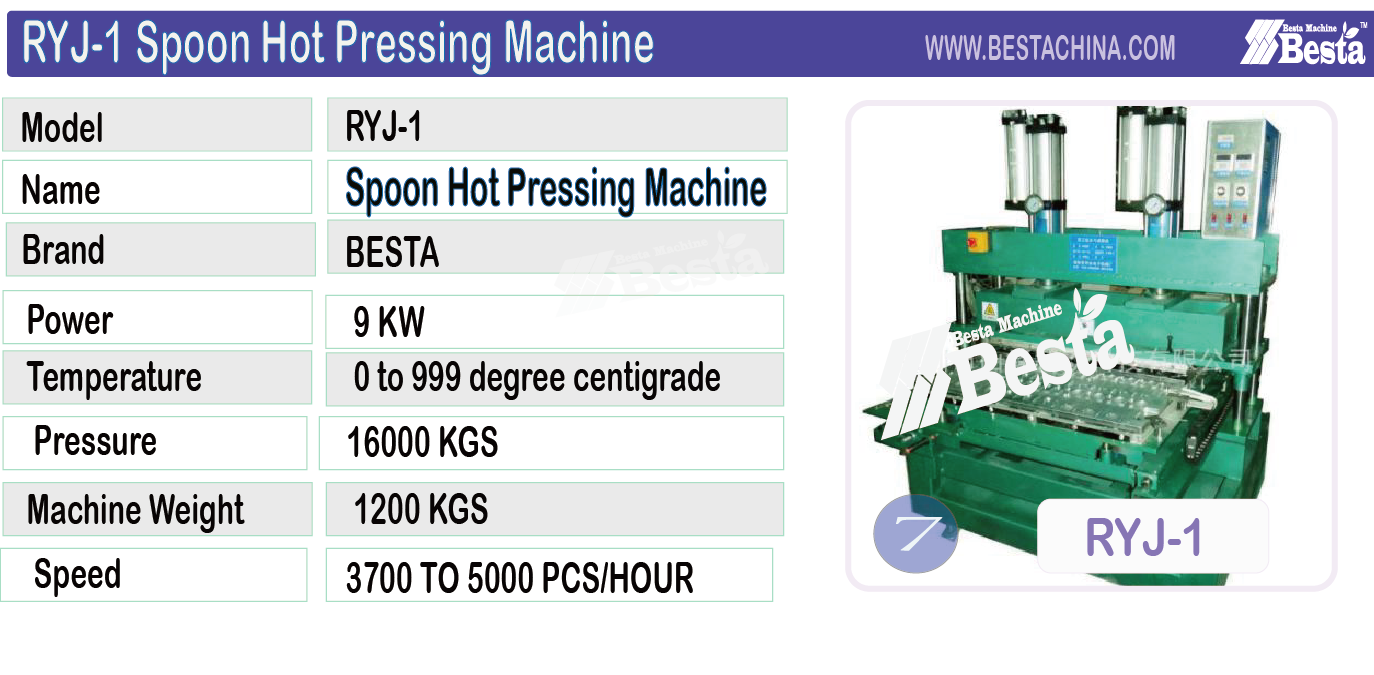

Disposable spoon making machine uses the gas-liquid pressurized cylinder and takes compressed gas as a power source, making use of compression section area ratio of the booster and Pascal principle of conservation of energy, which achieves the air pressure up to the number of times. then it is more easier to mold semi-finished cutlery products into end products by mould of spoon making machine.

The pressure is bigger, the noise is smaller, and the operation is stable. The spoon making machine has the temperature adjustment, time adjustment, pressure regulators, counting and other functions that be suitable for wooden spoon, knife and fork molding.

La máquina desechable para hacer cucharas usa el cilindro presurizado gas-líquido y toma gas comprimido como fuente de energía, haciendo uso de la relación de área de sección de compresión del amplificador y el principio de conservación de energía de Pascal, que logra la presión de aire hasta el número de veces. entonces es más fácil moldear los productos semielaborados de los cubiertos en los productos finales por el molde de la máquina que hace la cuchara.

La presión es mayor, el ruido es más pequeño y la operación es estable. La máquina de hacer cucharas tiene el ajuste de temperatura, ajuste de tiempo, reguladores de presión, conteo y otras funciones que son adecuadas para el moldeado de cuchara, cuchillo y tenedor de madera.

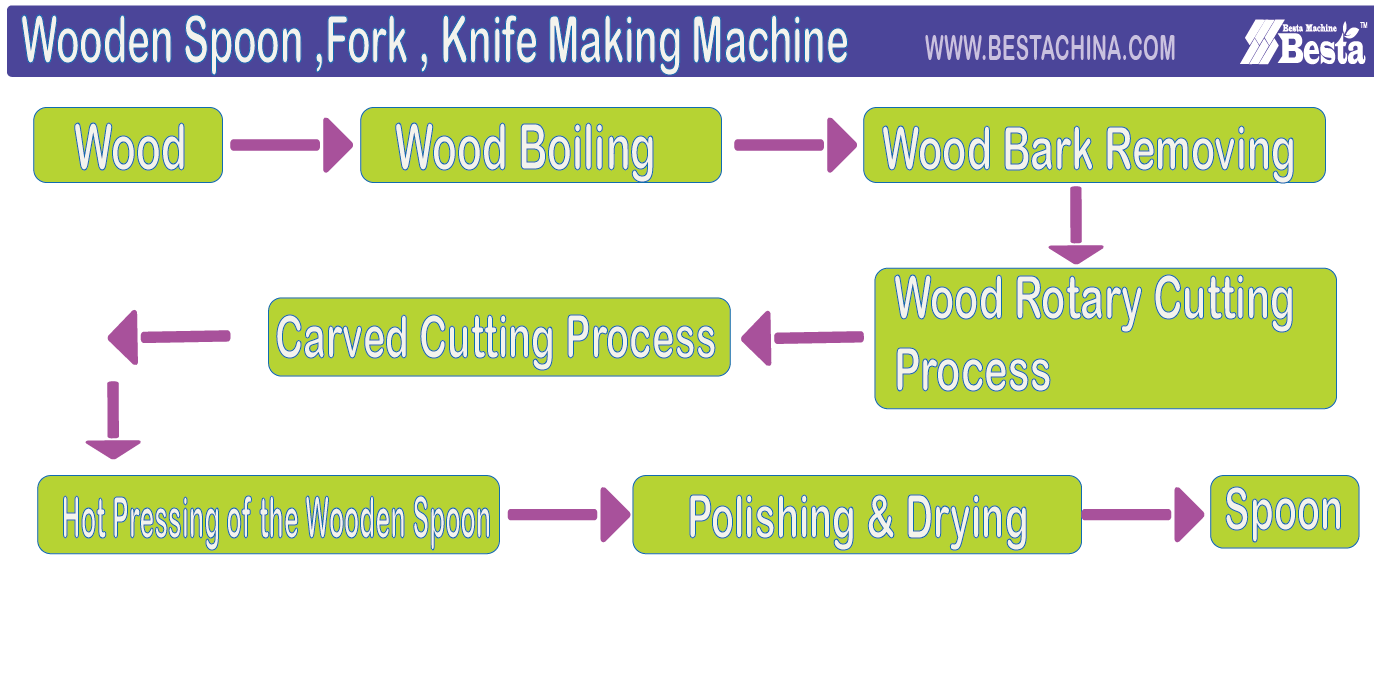

For wooden spoon, fork, knife and wooden plate line, it is mainly consisted by the following machine

For this line, it is consisted by the following machines,

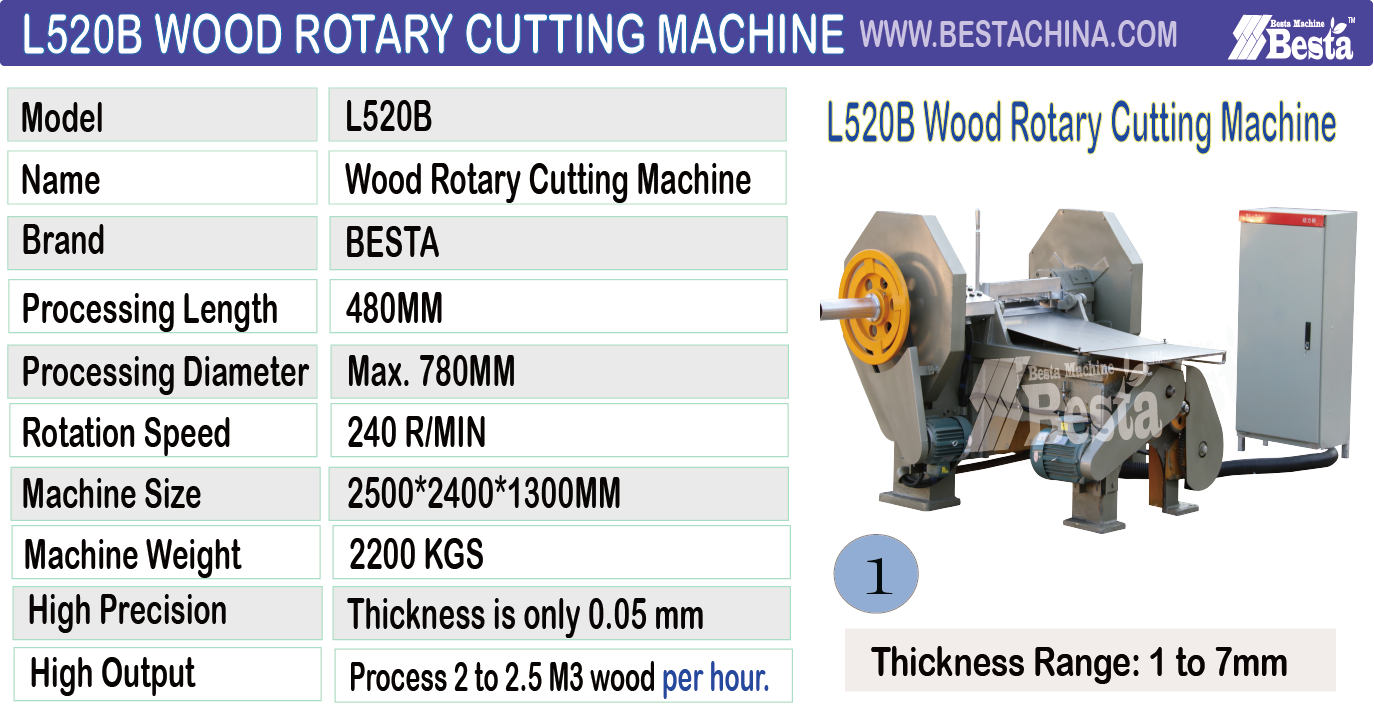

(1) L520B Wood Rotary Cutting Machine

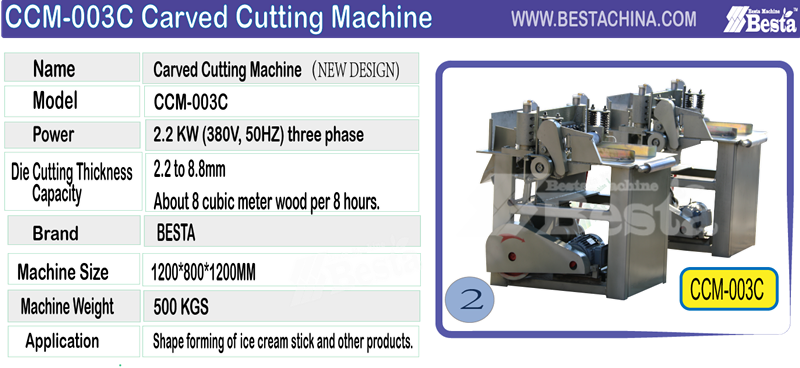

(2) CCM-003C Carved Cutting Machine

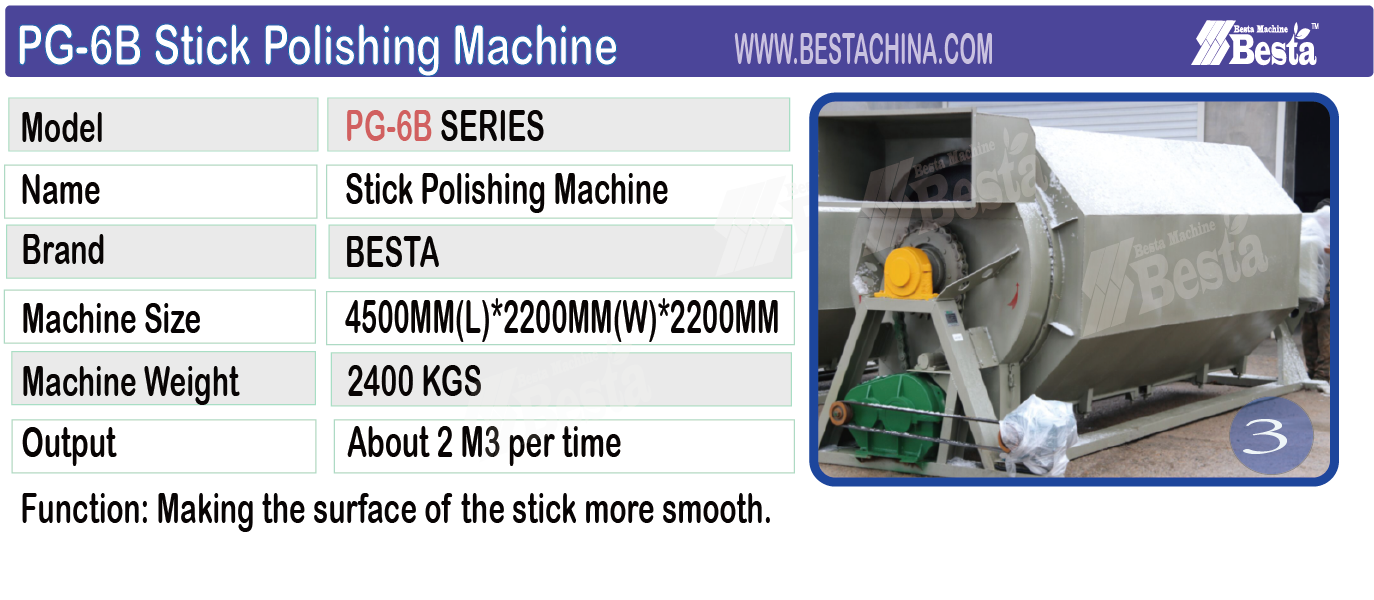

(3) PG-6B Stick Polishing Machine

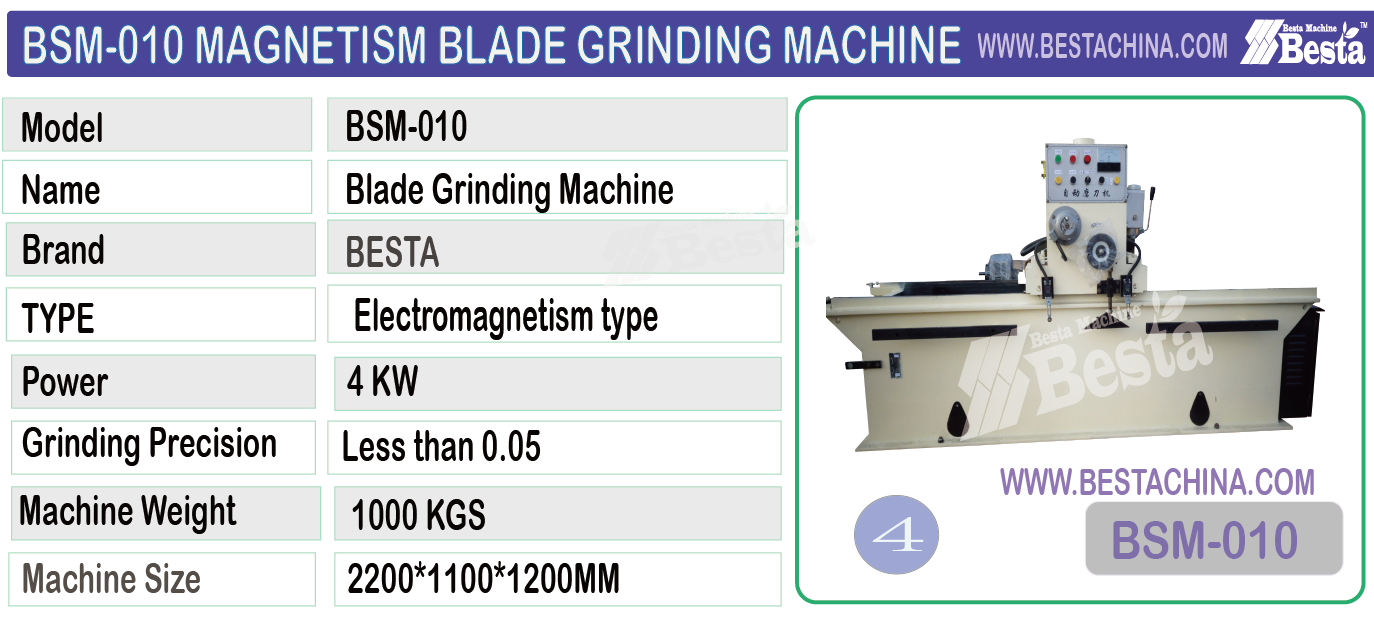

(4) BSM-010 Blade Grinding Machine (Magnetism type)

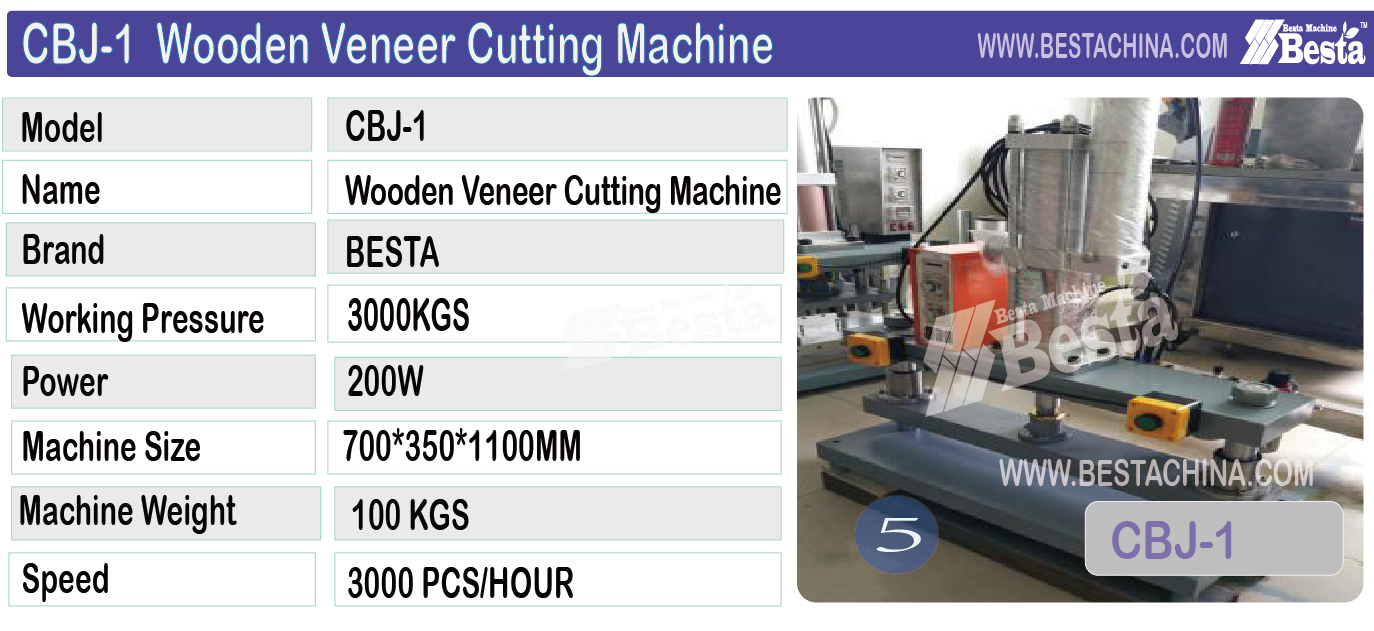

(5) CBJ-1 Wooden Veneer Cutting Machine

(6) KCJ-1 Wooden Fork Teeth Shape Forming Machine

(7) RYJ-1 Wooden Spoon Hot Pressing Machine

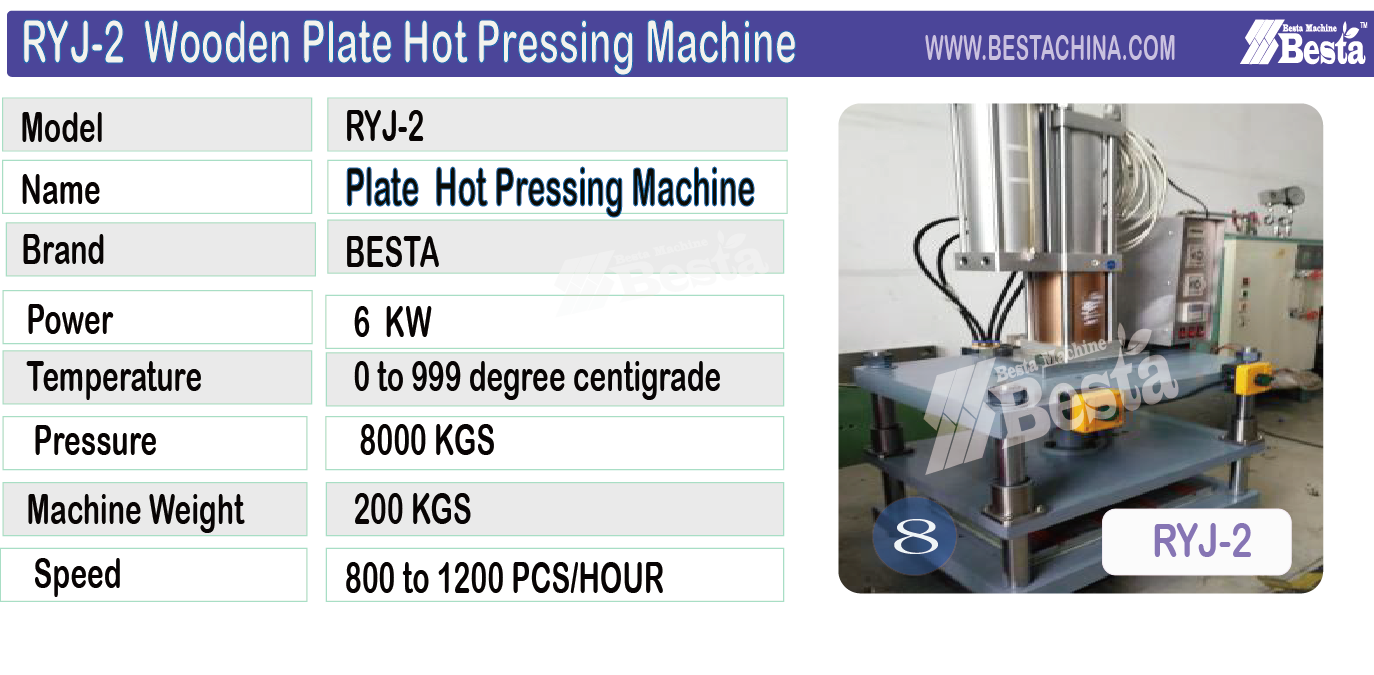

(8) RYJ-2 Wooden Plate Hot Pressing Machine

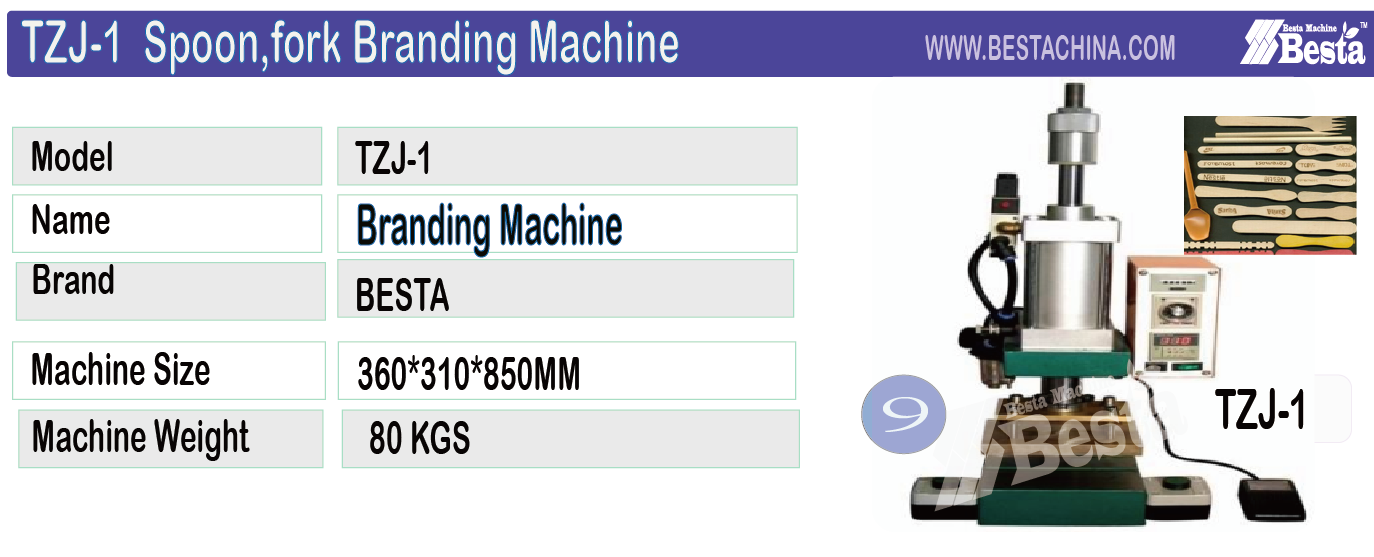

(9) TZJ-1 Wooden Spoon Branding Machine (Logo Printing)

BESTA BAMBOO MACHINE CO., LIMITED.

..........COM

EMAIL: info..........com, angelzhou1224..........com

MOB: 0086 186 5710 6860 (Whatsapp)

WOODEN SPOON HOT PRESSING MACHINE VIDEO

https://youtu.be/cDfxtqjT83w

<iframe width="560" height="315" src="https://..........com/embed/cDfxtqjT83w" frameborder="0" allow="autoplay; encrypted-media" allowfullscreen></iframe>