- Home

- About us

- Products

- Wooden Spoon Making Machine

- Wooden Ice Cream Stick Machine

- Wooden Tongue Depressor Stick Making Machine

- Wooden Coffee Stirring Stick Making Machines

- Wooden BBQ Stick Making Machine

- Wooden Toothpick Making Machine

- WOOD WORKING MACHINE

- Bamboo Toothpick Machine

- Bamboo Chopstick Machine

- Bamboo BBQ Stick Machine

- Bamboo Flooring Machine

- Bamboo Stick Making Machine

- Bamboo Charcoal Making Machine

- Bamboo Powder Making Machine

- Bamboo Toothbrush Machine

- Bamboo Spoon,Fork, Knife Making Machine

- Accessories

- Incense Stick Making Machine

- Plastic Machine

- BAMBOO PRODUCTS

- Other Projects

- Cotton Bud Making Machine

- New Machines

- Faqs

- News

- Certificate

- Contact us

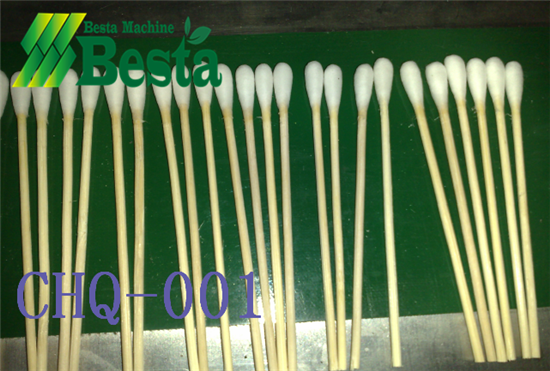

CHQ-001 Cotton Bud Machine

- group name

- Cotton Bud Making Machine

- Min Order

- 1 piece

- brand name

- Besta

- model

- CHQ-001

- Nearest port for product export

- Shanghai, Shenzhen, Ningbo

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C

- Export mode

- Export through agents

- update time

- Sun, 11 Mar 2018 09:38:03 GMT

Packging & Delivery

-

Min Order1 piece

Briefing

HIGH SPEED, CURRENTLY THE BEST MACHINES WITH HIGH QUALITY.

Detailed

CHQ-001 Cotton Bud Making Machine (using high quality parts)--Currently world latest model and best quality!

MODEL: CHQ-001

NAME: FULLY AUTOMATIC COTTON BUD MAKING MACHINE

TECHINCAL DATA:

POWER: 9 KW

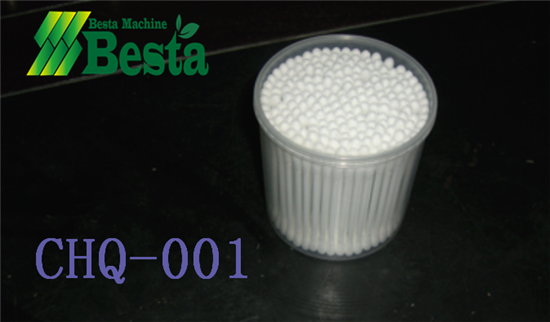

FUNCTION: MAKING COTTON BUDS, DRYING, PACKING (AN INTEGRATED FUNCTIONAL MACHINE)

MACHINE SIZE:Length: 9.5M*Width 1M*Height 1.6M

MACHINE WEIGHT: 1800 KGS

OUTPUT IN PRACTICE:800 to 1000 PCS/MIN

MAIN HIGH QUALITY PARTS IN THIS MACHINE

PLC : MITSUBISHI (JAPAN ORIGIN)

TOUCH SCREEN: WEINVIEW (TAIWAN)

INVERTER: DELTA (TAIWAN)

MAIN MOTOR: Yu-Xin (Taiwan)

MOTOR OF MANIPULATOR:

Mitsubishi(servo motor),Japan

PNEUMATIC SOLENOID VALVE: SMC, Japan

Fans: Yu-Xin (Yu-xin)

TRANSMISSION: Miki (Japan)

DISTRIBUTION BOX RELAYS: OMRON (JAPAN)

VIDEO LIINK OF CHQ-001 COTTON BUD MACHINE (FULLY AUTOMATIC )

Warm wind drying type packing machine adopts PLC program control,

automatic cotton using closed loop hot air drying technology, drying the

moisture in the running, and controlled by the servo motor drive screw

vacuum suction manipulator automatic packaging equipment to complete

the packaging link, from gluing, broken cotton, molding, drying,

packaging one-stop process. This machine is suitable for packaging

plastic valve bag and plastic drum, plastic boxes and so on

1. The peristaltic pump for the glue system, to ensure gluing evenly.

2. The two closed hot air drying system automatic cycle function; control swabs dry degree at six percent.

3. Servo motor screw track suck rod, make suck rod automatically more

smoothly, easy to adjust and operation.

4. The swab mould automatic positioning function, installation debugging.

5. The whole device eight kilowatts of power, actual power 7 kw, saves the electricity.

6. Mold since pressure molding to swab appearance more beautiful, to avoid the short cotton swabs.

7. Changes in the rate of the host, the computer automatic calculation,

automatic tracking, without having to adjust.

PACKING TYPES FOR YOUR KIND CHOOSE

..........COM

EMAIL: info..........com

Angel Zhou 0086 186 5710 6860 (whatsapp)